Unveiling Apple’s Revolutionary Recycling Robot: A Closer Look at Daisy

- Home

- Unveiling Apple’s Revolutionary Recycling Robot: A Closer Look at Daisy

Unveiling Apple’s Revolutionary Recycling Robot: A Closer Look at Daisy

Recycling Robot: In our exploration of Apple’s innovative strides, we delve into the heart of its Austin, Texas manufacturing hub to uncover the groundbreaking advancements in recycling technology, recycling Robot. At the forefront stands Daisy, a remarkable robot redefining e-waste management. Join us as we dissect the evolution of Apple’s recycling efforts and the pivotal role Daisy plays in shaping a sustainable future.

Apple’s Austin, Texas manufacturing facilities have been buzzing with innovation since 2013, crafting the iconic Mac Pro desktops just minutes away from the city center. With a burgeoning tech scene fueled by the nearby University of Texas, Austin has become a hub for technological breakthroughs. Amidst this backdrop, Apple’s $1 billion campus expansion project underscores its commitment to U.S. manufacturing, creating jobs, and driving sustainability initiatives.

The Mac Pro production line shares space with a modest yet pivotal recycling facility. Here, amidst industrial chutes and sorting systems, Apple’s vision for a carbon-neutral supply chain takes shape. Robotics, the unsung heroes of this green revolution, are poised to revolutionize e-waste management. Startups like Amp Robotics and Glacier pave the way with automation and AI, setting the stage for a paradigm shift in recycling efficacy.

Apple’s foray into robotics dates back to Liam, an early attempt to automate device disassembly. Liam 1.0 laid the groundwork, albeit slowly, for subsequent iterations. Liam 2.0 heralded a leap forward, slashing processing times and expanding compatibility. However, it was Daisy who stole the spotlight, ushering in a new era of efficiency and scalability.

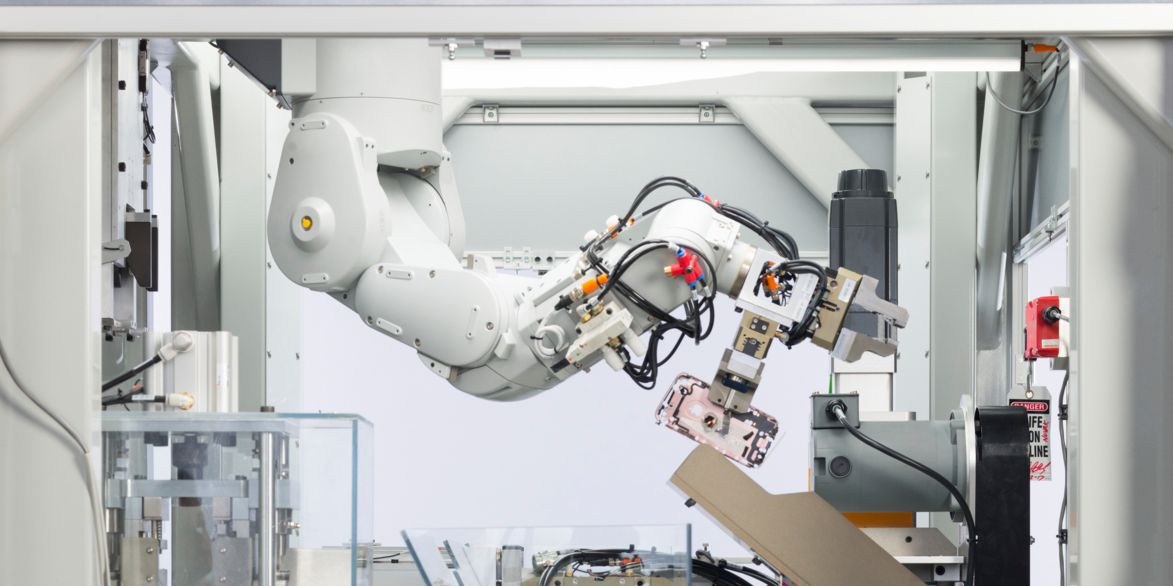

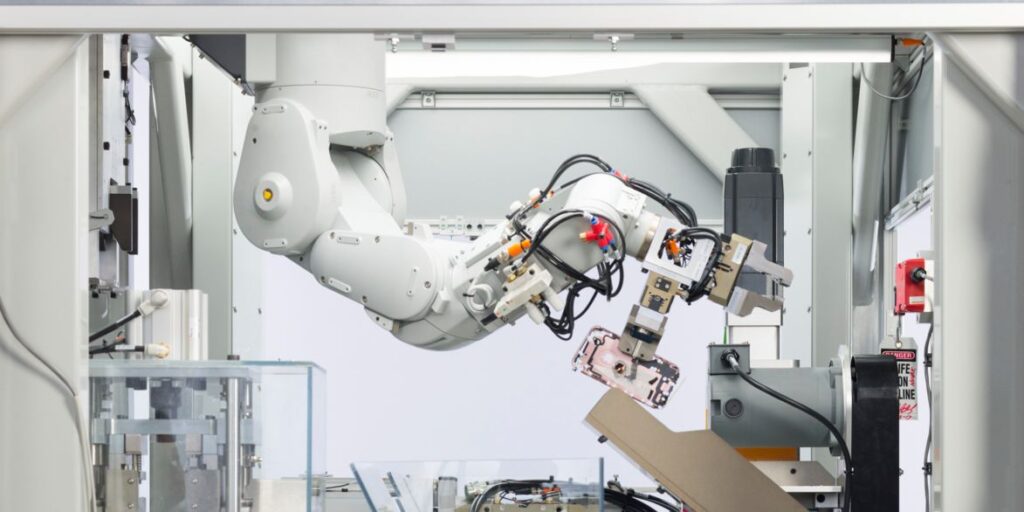

Daisy’s design embodies a fundamental shift in recycling methodology. Gone are the days of meticulous disassembly; Daisy opts for a more robust approach, tearing down devices with precision and speed. This transformation, while less aesthetically pleasing, maximizes throughput without compromising effectiveness.

Within Daisy’s chambers lies a symphony of automation and human oversight. From device intake to component separation, every step is meticulously orchestrated for optimal efficiency. Industrial robots, armed with AI and machine learning, collaborate seamlessly with human operators to streamline the recycling process.

Despite Daisy’s remarkable capabilities, the journey towards comprehensive e-waste management is far from over. With millions of smartphones discarded annually, the scale of the challenge is immense. Education and consumer engagement remain critical in driving meaningful change. Apple’s efforts to raise awareness through initiatives like Daisy exemplify its commitment to environmental stewardship.

Looking ahead, Apple envisions Daisy as a catalyst for industry-wide collaboration. By sharing its IP patents and fostering partnerships, the company seeks to amplify the impact of recycling robotics beyond its ecosystem. With continuous innovation and cross-disciplinary collaboration, the future of e-waste management looks promising.

As Daisy continues to evolve, so too does Apple’s commitment to sustainability. With robotics at the forefront of its recycling efforts, the company is poised to redefine the landscape of electronic waste management. Through innovation, education, and collaboration, Apple paves the way for a greener, more sustainable future.

Also Read >> Binit’s Innovative Approach: AI Revolutionizes Trash Tracking

- Share